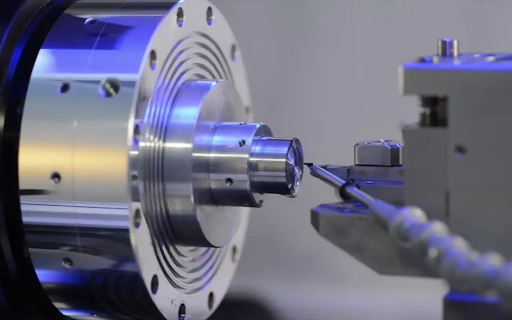

In contemporary manufacturing, obtaining extreme accuracy and close tolerances is imperative in many industries. Ultra-precision machining is a unique process that guarantees the utmost precision, even reaching tolerances at the sub-micron level. Ultra-precision machining is an advanced machining method applied in sectors where regular machining cannot achieve the desired precision standards. The following are some major applications of ultra-precision machining in various industries.

1. Aerospace Industry

The aerospace industry requires precision in all aspects, ranging from engine parts to navigation systems. Ultra-precision machining is essential in producing turbine blades, fuel injectors, and structural parts that have precise specifications. The capability of handling high-performance materials such as titanium and Inconel while ensuring extreme precision guarantees safety and efficiency in aerospace use. Even slight variations in component size can result in flight performance problems or flight failure, which is why precision machining is a must in this sector.

2. Healthcare and Medical Equipment

Medical equipment and surgical instruments need flawless precision to provide reliability and function. Ultra-precision machining is employed in making medical implant components, prosthetic components, and surgical devices. Equipment like pacemakers, orthopedic implants, and dental implants rely on accurate machining to satisfy stringent industry standards and patient safety requirements.

The process is also critical in the creation of microfluidic devices employed in diagnostics and drug delivery systems. As the need for minimally invasive medical procedures increases, ultra-precise machining is increasingly being used in the manufacture of small-scale, high-accuracy medical devices.

3. Optics and Photonics

Optical devices like lenses, mirrors, and prisms require sub-micron accuracy to ensure clarity and performance. Ultra-precision methods are applied to produce high-precision optical components for cameras, telescopes, microscopes, and laser systems. Photonics technology also depends on the machining method to create fibre-optic communication equipment and high-precision laser components. Small flaws in these components can corrupt light transmission, impacting image clarity and system performance.

4. Semiconductor Manufacturing

The semiconductor manufacturing industry demands precision of the highest order in manufacturing microchips and circuit boards. Ultra-precision machining is applied to produce sophisticated silicon wafers, guaranteeing the right operation of electronic devices. With this machining process, manufacturers can fabricate microelectromechanical systems (MEMS) and nano-scale components that form the backbone of contemporary technology.

With the increasing demand for smaller and faster electronic devices, the use of ultra-precision machining in semiconductor manufacturing has become increasingly important. The technique also assists in the development of highly efficient cooling systems for electronic devices, which is crucial for enhancing performance and lifespan.

5. Defense and Military Applications

The defense sector depends on ultra-precision machining for manufacturing sophisticated weapons, navigation systems, and surveillance tools. Parts like missile guidance units, night vision lenses, and communication systems need ultra-accurate manufacturing to perform flawlessly in critical operations. Military and defense use involves harsh environmental conditions, including high-impact forces, extreme temperatures, and exposure to corrosive materials. Ultra-precision machining makes the parts meet the highest standards of durability and reliability to endure these conditions.

6. Automotive and Motorsport

High-performance motorsports and high-performance vehicles call for precision parts that improve safety, efficiency, and speed. Ultra-precision machining is utilized in the fabrication of engine components, fuel systems, and brake components. For the luxury market and electric cars, precision machining provides maximum component performance and component lifespan.

Due to the increased emphasis on autonomous and electric cars, ultra-precision machining will play an even more significant role in creating detailed sensor systems as well as battery components that demand high accuracy as well as ruggedness.

7. Watchmaking and Jewelry Industry

Fine jewelry and luxury watch demand meticulous craftsmanship with intricate details. Ultra-precision machining is extensively applied in producing watch movements, gears, and cases. The capability of working with costly metals and obtaining microscopic tolerances ensures quality, rugged, and visually attractive products. High-precision machining enables the production of one-of-a-kind, intricate designs that contribute to the higher value and attractiveness of luxury items.

8. Research and Development

Universities, research facilities, and laboratories employ ultra-precision machining to create experimental models, scientific tools, and space exploration equipment. Precision machining is essential for producing nanoscale devices, satellite parts, and quantum computing devices. Precision at the atomic level is needed by these industries in order to provide proper functionality for cutting-edge technology. From creating high-resolution imaging systems to building ultra-sensitive sensors, precision machining is essential to further scientific studies and innovation.

Conclusion

Ultra-precision machining is an essential process in industries that demand the utmost accuracy and consistency. In aerospace and medical devices, semiconductors, and automotive uses, this sophisticated machining process guarantees high-performance parts that pass strict quality requirements. For high-precision parts demanded by industries, Gemsons Precision Engineering Private Limited (GPEPL) offers world-class machining services with decades of experience and state-of-the-art technology.

With their EN 9100:2018 approved Aerospace Cell and dedication to excellence, Gemsons guarantees unmatched precision in production, thereby becoming a reliable partner for those sectors requiring the highest standards of quality.

Recent Comments