Real-World Challenges in 5-Axis CNC Machining and How to Overcome Them

The incredible part of 5-axis CNC machining lies within the integration of simplification and complexity in the manufacturing process. All that for an intricate design, high precision, and quicker production time offers it all. But with this power comes a set of...

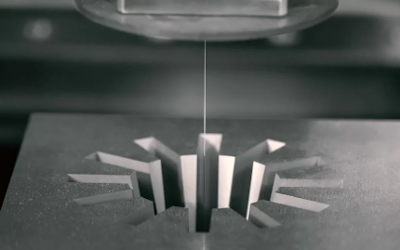

How Wire EDM Machining Enhances the Production of High-Tolerance Parts

Precision is everything in manufacturing, especially when it comes to producing high-tolerance parts. Aerospace, medical devices, and electronics require tightly specified parts where minute deviations will lead to failure. This is where Wire EDM steps up. It is a...

Applications of Ultrasonic Cleaning: From Industrial Equipment to Jewelry Care

Ever wonder how delicate jewelry pieces and gigantic industrial equipment are cleaned with the same level of accuracy? It all hinges on the advanced technique of ultra sonic cleaning, which works well for both purposes. From more complex jewelry pieces to smooth...

Impact of Material Selection on cost and Performance of custom parts

Material selection is a critical factor that influences both the cost and performance of custom parts. Whether you're designing components for aerospace, automotive, or industrial machinery, the choice of material can determine the project's success. By understanding...

The Key Differences- Forging vs CNC Machining

When manufacturing high-quality components, two of the most commonly used processes are forging and CNC machining. Each of the methods has its benefits and it is up to you to decide which of the methods will be used in a particular project as per your distinctive...

Choosing the Right Material for Your CNC Machining Project

Whether working on a small-scale or a large production run, selecting the appropriate material can majorly impact the machining process, cost, and product performance. Choosing the right material for your CNC precision machining project is crucial to ensuring the...

What Die Casting Process Should You Use for Your Designs and Products?

Choosing the right die-casting process is critical for ensuring the quality, efficiency, and cost-effectiveness of your product manufacturing. Die casting is the most versatile and used manufacturing process, involving forcing molten metal into the mold cavity under...

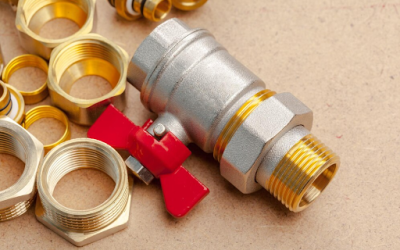

Beyond the Button: The Intelligent World of CNC Valve Control Systems

In the ever-evolving world of industrial automation, CNC (Computer Numerical Control) valve control systems have emerged as a revolutionary technology. These systems are transforming various industries by offering precision, efficiency, and intelligence far beyond...

Why The Cleaning Process Is Required In The Manufacturing Of CNC Machining Parts

The manufacturing of CNC (Computer Numerical Control) machining parts involves precision engineering and intricate processes to produce high-quality components used across various industries. One often overlooked yet critical step in this manufacturing process is...